Motor Retention

|

Several options are available. Some must be added during contruction. Some can be added after a rocket has been finished.

Examples

A common practice is to install a #6 T-nut (also called a blind nut) into the aft centering ring. A hole is drilled into the ring for the barrel of the T-nut. The pointed anchors can be flatted because most centering rings are too thin to use them. A little epoxy around the edge of the T-nut will hold it in place. A screw can

then be used to keep the motor in the motor mount tube.

A common practice is to install a #6 T-nut (also called a blind nut) into the aft centering ring. A hole is drilled into the ring for the barrel of the T-nut. The pointed anchors can be flatted because most centering rings are too thin to use them. A little epoxy around the edge of the T-nut will hold it in place. A screw can

then be used to keep the motor in the motor mount tube.

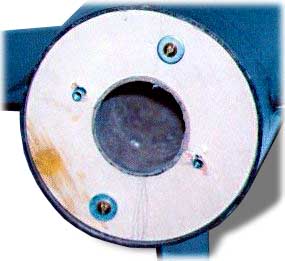

You can see the barrels of two T-nuts protruding through the centering ring in this picture. The flat part goes behind the centering ring.

You can see the barrels of two T-nuts protruding through the centering ring in this picture. The flat part goes behind the centering ring.

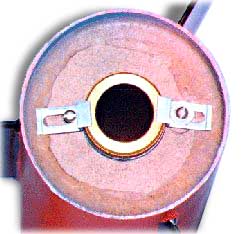

This example uses a "panel clip". The clip is held in place by a screw into the T-nut installed in the centering ring. A panel clip is used on screen doors, and can be found in hardware stores in the section with screen door repair parts. The slot in the clip is part of the clip.

This example uses a "panel clip". The clip is held in place by a screw into the T-nut installed in the centering ring. A panel clip is used on screen doors, and can be found in hardware stores in the section with screen door repair parts. The slot in the clip is part of the clip.

A simple washer can be used with a screw screwed into a T-nut installed in the centering ring.

A simple washer can be used with a screw screwed into a T-nut installed in the centering ring.

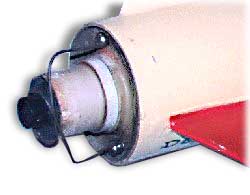

A retainer made from wire works with single use motors.

A retainer made from wire works with single use motors.

A screw and nut are used to retain this cluster. The screw is epoxied into the rocket. The nut unscrews to release the motors.

T-nuts cannot be added to an already constructed rocket. However, expansion bolts and other devices available in any hardware store can be also be used to add positive motor retention to an assembled rocket. Some companies have screw-on retainers that can be added to existing rockets.

Submitted by Dean Roth

Website, HTML code & graphic design by Darrell Mobley. Site optimized for Netscape and Microsoft Internet Explorer browsers.