There are several great brands of epoxies on the market today. For larger rockets it makes sense to buy epoxies in quantities larger than you find in the hobby store. West System and System 3 are two of the more popular brands and are widely available around the world. These can be purchased in quart and pint quantities and can be had with nifty pump dispensers that take the guesswork out of mixing. In my experiences the West System and the System 3 epoxies are pretty good for doing all types of rocketcrafting. Here’s what you need:

- Your choice of epoxy, choose a slow and a fast hardener so that the two can be intermixed depending on the temperature.

- A bottle of milled fiberglass to go with your choice of epoxy as an admixture

- cab-o-sil is also an effective additive

- wood flour also works well in some places

- microballoons are lightweight and sand nicely

- chopped fiberglass is also a good additive

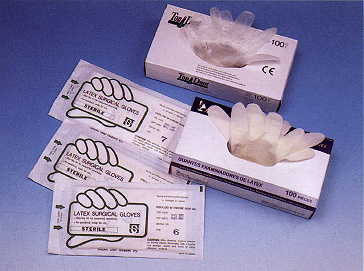

- a box of gloves

- some cheapo brushes

- a quart of denatured alcohol

- a shopping bag with a bunch of baby powder in it

- a legal pad

- popsicle sticks and you are all set.

If you’re switching from the 3 oz hobby store bottles to the larger economy size the initial cost is greater at first, especially if you get the pumps, but the long run saving is quite impressive. Epoxy lasts a loooooong time, so you needn’t worry about that. Polyester goes off after a while plus is smelly to use, forget that stuff IMHO.

Milled fiberglass is just that, finely chopped fiberglass looking almost like sand or dust. Equal parts epoxy and fiberglass is a wonderful mix that stays exactly where you put it and is super strong. Using epoxy without an admixture is a total pain unless you are laying something up or glassing a tube. Even then, the pros often include an admixture to extend the epoxy, making it more workable, cheaper to use, and not so runny. There is also talc, cab-o-sil, microballoons, and more but they all have different properties. Worth trying out and playing with though, the marine stores might have this stuff.

| CONSISTENCY | Unthickened mixture | Slightly thickened | Moderately thickened | Maximum thickness |

|

|

|

|

|

| APPEARANCE | Like syrup | Like catsup | Like mayonnaise | Like peanut butter |

| CHARACTERISTICS | Drips off vertical surfaces | Sags down vertical surfaces | Clings to vertical surfaces; peaks fall over | Clings to vertical surfaces; peaks stand up |

| USES | Coating; wetting-out before bonding; applying fiberglass, graphite and other fabrics | Laminating/bonding flat panels with large surface areas, injecting with a syringe | General bonding, filleting, hardware bonding | Gap filling, filleting, fairing, bonding uneven surfaces |

Source: West System instructions

Supplies

Latex or vinyl gloves are indispensable. They keep your hands clean and protected; they’re cheap too.

The cheapo brushes are often called “chip” brushes and cost half a buck each. They have a blond bristle, buy 10 or so.

Denatured alcohol is good for cleaning up goofs, smoothing fillets, and thinning epoxy. Most manufacturers don’t recommend adding it to the epoxy mixture because the epoxy can lose about 30% of it’s strength depending on how much is added. If it just won’t thin out once it’s where you want it, use a heat gun or hairdryer and the epoxy will run like syrup.

That is, until it starts to congeal or cook off. Once the epoxy gets up to 150 degrees or so throughout the entire mixture, it will harden so you have to be careful. You can use this in your favor too. On the flip side, heat also destroys epoxy so you have to be careful. The shopping bag and talc is to save your gloves and your sanity.

Epoxy is super sticky and it gets everywhere! Everything sticks to your fingers and it can be a nightmare. Dump the canister of baby powder in the bag. Whenever you are done with a task and your gloves are sticky rustle your hands around in the bag. The talc wicks up the epoxy right now and it falls off your gloves. Clap your hands and the talc falls off so you don’t contaminate your work with dust. This is especially cool if you are laying up fiberglass and cutting glass at the same time. The scissors become a gummy mess and the glass sticks to your fingers. Yuck. You can use this stickiness in your favor though when you lay up a part or glass a tube. If the epoxy is brushed on the tube and allowed to cure a bit it becomes sticky and the glass sticks like magic. Then it’s a snap to lay on a couple of layers in just minutes with the right jigging and fixturing. But I digress.

I use a legal pad when I’m mixing up smaller batches. I dispense appropriate amounts on the paper and use a popsicle stick to stir it up. When the sheet is full of used batches I tear it off and throw it away revealing a clean work surface.

The popsicle stick also describes a nice radius on the filet. You can also find smaller dixie cups that are waxed paper with graduations on the side. Doctors use them a lot for dispensing drugs. With the West Systems the mix is 3 to 1 so if I’m making a smaller batch I find the 5 dram mark and fill it with hardener and then fill it up to the 20 dram mark with resin. dram or milliliter or 1/2 teaspoon or whatever measure you choose. Piece of cake. Last thing that is especially nice is warm epoxy. If you have a bucket or large pot fill it with hot water from the tap and dunk the bottles of resin and hardener in it.

The epoxy pumps smooth and evenly and is about as thin as it’s going to get. What happens when you mix epoxy cold is that it is gluey and gloppy at first then starts to run as it heats exothermically causing all kinds of grief. If it’s already to that temperature when mixed then there are no surprises. You do have to be careful that it doesn’t stay in the pot too long else it will bubble and start to smoke–exotherm. That’s pot life. When you spread it out on your work the reaction slows and you are able to manipulate it, that’s called open time. If your piece is at room temperature and the epoxy is warm, you should have no surprises. Often if you use pumps for the two parts and you warm the bottles, the liquid is warm but the material in the pump is cold and the ratio can be off. This is especially true if the bottles have been stored outside. It might take a couple of pumps before it dispenses accurately. Ideally try to do all your epoxying at one whack. Admixtures like milled fiberglass allow you to do this since the material stays put. Heat guns and hair dryers also help as does a warm part and working area. If you have to go back over a cured epoxy, let’s say the next day, you often need to remove the amine blush that develops on the surface by sanding or washing. Paper tubes and plywood fins don’t lend themselves to washing so it’s time for the sandpaper. If all the epoxy work is done over the course of a couple of hours then this mess is eliminated. Have fun and remember, the sticky side always goes towards the rocket.

Submitted by: Bob Fortune