Reloadable Motors

|

|

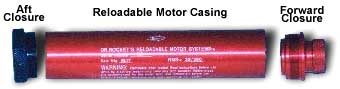

Pictured is a Dr. Rocket/Aerotech reloadable motor. On the left is the aft closure, which closes the rear of the motor and holds in the nozzle, the motor case and on the right the forward (top) closure. (Dr. Rocket is a licensed manufacturer of Aerotech's motor technology.)

The aft closure is slightly larger than the case. When the motor is inserted into the motor mount tube the lip keeps the motor from moving up through the motor mount tube and rocket when thrusting.

Motor cases are available in different diameters and lengths to allow

for propellant kits of different size and total energy.

A propellant reload kit contains one or more propellant grains, and other components that are replaced each time the motor is used. Most motors use one or more silicone O-rings that must be replaced each time the motor is used. Some manufacturers use a plastic nozzle that must be replaced for each motor use. Others use a graphite nozzle that is usually good for about 20 flights before replacement is needed.

|

This is an AeroTech reloadable motor reload kit, which can be used with either an AeroTech RMS� or Dr. Rocket reloadable motor.

This particular kit, an H-123, contains two individual propellant grains, a cardboard motor case liner, rubber O-rings, a single-use plastic nozzle, a delay grain and components, and assorted seals.

The propellant grains are inserted into the liner, and the liner is then inserted into the motor case.

|

Shown here is an Advanced Propulsion Systems (APS) reloadable motor. The motor consists of a case, forward closure, aft closure (next to the nozzle) and graphite nozzle. The nozzle can be used for about 20 flights before replacement.

|

|

Black powder is placed into the well, and cover with some masking tape to hold it in, when motor ejection is used to deploy the parachute. A small hole is in the bottom of the well so that the black powder is in contact with the top of the delay grain. When the delay grain burns through the black powder is ignited.

When an electronic mechanism, such as altimeter, is used to activate the ejection charge, a plugged forward closure may be used if offered by the motor manufacturer. A plugged closure is like the pictured one but the top is solid, having no ejection well or hole.

|

The motor must be ignited from the top, not near the nozzle. The igniter must be fully inserted into the motor.

Motors must be cleaned between uses. Insufficient cleaning, or reusing old parts can result in hot gas leakage and motor and rocket destruction. Motors can be field cleaned using foil wrapped, wetted towels which are sold under several brand names in grocery and other stores.

The silicone O-rings must have a light coat of lubricant ("grease") applied to them when they are installed. The lubricant allows the closures to slide over the rings without crimping or tearing them when the closures are installed and tightened. Following the manufacturer's instructions. The O-rings should have only a light coating - just enought to give them a sheen. Too much lubricant can result in motor failure. Too much lubricant on O-rings near the forward closure, where the ejection delay grain is located, can result in failure of the delay grain to ignite if the lubricant gets on the faces of the grain. (Dirty hands can also cause the delay grain to become contaminated with lubricant.) If the delay grain fails to burn and motor ejection is used to deploy the recovery system the rocket will crash and crumple, hopefully not damaging any person or other property.

The particular type of lubricant used (petroleum jelly, grease with Teflon, etc.) is not nearly as important as the correct application of the lubricant.

Submitted by Dean Roth