Composite Clustering

|

Delivering all the current that the igniters can consume is an important aspect of successful clustering of composite motors. This is especially true where high current ignitors are employed in conventional launch systems. 4 high current ignitors wired in parallel, such as Firestars or thermalite can draw in excess of 50 amps of current. If your system can't deliver that kind of power, the results could be the ignitors firing sequentially rather than simultaneously.

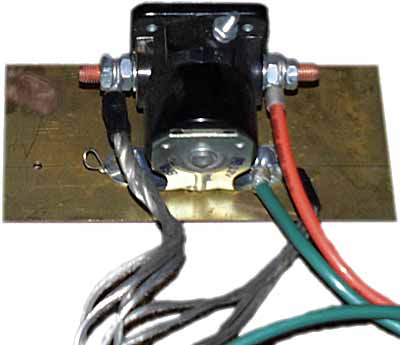

To address this issue, we designed a low resistance, high current ignition system from parts found at your local auto supply store. The current switch in this setup is a Ford Starter solenoid, which has contacts rated at several hundred amps. The large connection lugs and the use of beefy battery cables reduce resistive losses. This system useds 8 ga wire with soldered connectors from the battery to the solenoid as it was available at no cost. Purchasing pre-made battery cables will simplify the construction. Four sets of igniter leads make this setup useful for drag races and also the smaller wires offered allot more lead flexibility over the 8 ga wire used for the battery leads. The best of all situations would be to find a flexible large gauge wire for the launch leads.

Using the cluster ignition system is quite easy. Attach the battery leads to a well charged battery and the from the solenoid leads to the ignitors. Then attach the leads from the launch control system to the terminals of the solenoid, the #10 stud is one terminal and the metal frame of the solenoid is the other. Polarity between the launch system and the solenoid is not an issue here as long as the battery attached to the solenoid is not connected to any other launch gear. Continuity testing at the launch controller is not an issue, as the actuation current for the solenoid is about 2 amps.

Submitted by John Lyngdal