Solderless Igniters

| GROUND SUPPORT |

|

Launch Pads

Firing Consoles Clip Whips Build a Launcher Build a Launch Pad Multi-Pad Launcher Solderless Igniters Copperheads Cluster Wires |

|

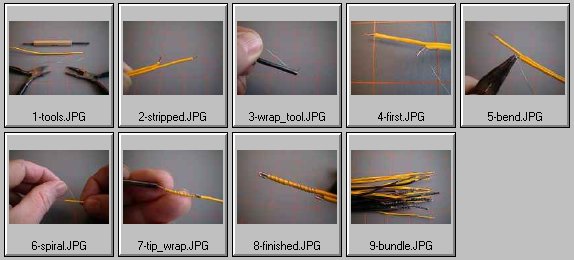

The thumbnail images below are clickable links to the photos referenced in the article.

Click on the thumbnail of the photo you wish to view.

Use your browser "back" button to return to this page.

This article describes a solderless method of securing the nichrome to the leads. It has been 100% reliable to date (several hundred igniters).

Photo 1:

Get a wire wrap tool. Radio Shack has cheap ones. Electronics suppliers

have better quality ones. Either will work. You will also need a small

pair of needle nose pliers and a small pair of wire cutters.

Cut your nichrome about 1/2"-1" longer than normal. How much extra length depends on how much manual dexterity you have. The author can get by with 1/2" extra, but an extra inch is easier to work with, and the cost difference is about 0.25 cents--1/4th of one cent--per igniter.

Photo 2:

Trim and strip the lead wire as shown.

Photo 3:

Thread the nichrome through the side hole in the wire-wrap tool with about 1/4" sticking out

the end.

Place the center hole of the wire-wrap tool over the shorter lead conductor as if that lead were a wire-wrap post on a pc board.

hold the 1/4" nichrome (sticking out the end of the tool) against the igniter leads and give the wire-wrap tool about 6-7 turns.

Photo 4:

Carefully pull the wire wrap tool off the lead wire. You should now have a very neatly wire-wrapped piece of nichrome secured to the copper lead.

Photo 5:

Either trim off the extra copper wire beyond the end of the nichrome, or bend it over in

a U against the nichrome coil. (I prefer to bend it and crimp it against the nichrome) Trim away the 1/4" of nichrome you held against the leads in the previous step.

Photo 6:

Spiral the nichrome up the longer lead to the tip the required number of turns for your

application. You should have about 1/2"-3/4" of nichrome left.

Photo 7:

Thread this short length back up the side hole in the wire wrap tool.

Thread it in from the end of the tool, not the side slot as you did the

first time. Carefully place the copper lead wire in the "post" hole of the

wrap tool, being careful not to pull the nichrome out of the "wrap" hole.

Be careful, it's easy to get both wires in the same hole on the tool--that

won't work and will probably break your remaining nichrome off too short!

Give the wire-wrap tool 6-7 more turns until all the remaining nichrome is wrapped around the end conductor.

Trim or bend as in the first one.

Photo 8:

Voila! a solderless lead.

Check your continuity & resistance to make certain that you have not changed the nominal resistance of the lead compared to your soldered leads.

It actually takes longer to describe this process than it does to do it. With a little practice, you should be able to produce them as fast or faster than by the solder method without all the hassle and mess of setting up the solder station, etc.

Submitted by Jim Ball